What Are Silicone Thermal Interface Materials and Why Does It Matter

As electronic devices grow more powerful and compact, effective heat management is essential.Silicone thermal interface material plays a key role by providing excellent thermal conductivity, flexibility, and high-temperature stability, efficiently connecting heat-generating components to heat sinks. In this article, we’ll explore what silicone thermal interface materials are, how they work, and why they matter in today’s electronics.

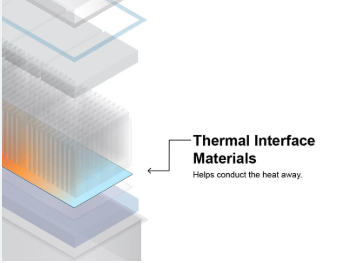

What Is a Silicone Thermal Interface Material (TIM)?

A Silicone Thermal Interface Material (TIM) is a silicone-based compound that helps transfer heat from hot components like CPUs or GPUs to cooling parts like heat sinks. It fills tiny air gaps between surfaces to improve heat flow, preventing overheating and keeping devices running efficiently.

Purpose

The main goals of silicone TIMs are to:

- Improve Thermal Contact: Fill microscopic gaps between surfaces to create better heat flow.

- Reduce Thermal Resistance: Replace air with a material that conducts heat more efficiently, helping to cool the device faster.

Silicone TIMs improve heat transfer between electronic parts and cooling systems, helping devices stay cooler and last longer.

How Silicone TIMs Work

Silicone TIMs are soft, heat-conductive materials used to fill microscopic air gaps between electronic components (like CPUs, GPUs, LEDs) and their heatsinks, enabling better heat transfer. How they work:

- Filling Gaps

Chips and heatsinks make limited direct contact (~5–10%). Silicone TIMs conform to surface irregularities, replacing air (a poor conductor) with a heat-conductive path.

- Composite Structure

Made of silicone polymer mixed with thermally conductive fillers (e.g., aluminum oxide, boron nitride, zinc oxide), improving thermal conductivity from ~0.2 to 1.5–12 W/m·K.

- Thermal Resistance Depends On:

- Material thermal conductivity.

- Bond line thickness (BLT): Thinner is better.

- Surface contact quality (wettability and pressure).

Silicone TIMs are cost-effective, reliable materials that enhance heat transfer in electronics by replacing air with a thermally conductive layer. For sensitive or high-performance applications, specialized alternatives (like non-silicone or liquid metal TIMs) may be required.

Key Properties of Silicone TIMs

- Thermal Conductivity: Typically 0.5–5 W/m·K, with special types up to ~16 W/m·K. Heat transfer efficiency also depends on thickness and pressure.

- Electrical Insulation: Excellent insulators with high resistance and strong dielectric strength, preventing unwanted electrical flow.

- Temperature Stability: Stable across –55°C to 200–240°C; resistant to breakdown and oil loss at high temperatures.

- Thermal Aging & Cycling: Remain flexible and non-brittle after prolonged heat exposure and repeated thermal cycles.

- Chemical Resistance & Aging: Resist UV, ozone, chemicals, and oxidation; may slightly harden over time but retain core properties.

- Long Service Life: Durable for demanding applications like aerospace, automotive, and outdoor electronics.

- Reworkability: Often removable and replaceable without residue, unlike permanent materials.

- Easy Handling: Available in various forms, simple to apply manually or automatically.

Types of Silicone TIMs

- Thermal Greases/Pastes: Silicone-based material with heat-conductive particles.

- Pros: Very good at conducting heat, especially in thin layers.

- Cons: Messy and needs careful application.

- Used for: High-performance electronics where efficient cooling is important.

- Silicone Pads: Soft silicone sheets with thermal fillers, pre-cut.

- Pros: Easy to use, good for automated assembly, keeps consistent thickness.

- Cons: Doesn’t fit very uneven surfaces as well as greases or gels.

- Used for: Used in everyday electronics, car parts, and any place where consistent heat control is important.

- Gels and Adhesives: Gels and adhesives conduct heat while securely bonding parts together.

- Pros: Good for permanent or semi-permanent bonding and filling bigger gaps.

- Cons: Silicone TIMs can be difficult to remove, and adhesive versions require curing time to achieve full effectiveness.

- Used for: Applications where parts must be securely attached and cooled, like power modules.

- Gap Fillers and Dispensable TIMs: Gap fillers and dispensable TIMs are thick, flowable materials used to fill uneven or large gaps.

- Pros: Great for uneven or large surfaces; conforms to complex shapes.

- Cons: Requires dispensing equipment; manual application can be tricky.

- Used for: High-power electronics, LEDs, and places with varying gap sizes.

Silicone TIMs Advantages and Considerations

- Advantages:

- Conduct heat well (2–4 W/m·K), reducing overheating by filling tiny gaps.

- Stable in extreme temperatures (–50 °C to +180 °C+).

- Resistant to moisture, UV, oxidation, and aging, making them ideal for harsh environments.

- Flexible and fills small or uneven gaps easily.

- Chemically safe and non-corrosive, resistant to harsh chemicals.

- Considerations:

- Higher cost for advanced silicone types.

- Non-curing greases may dry out or move, needing reapplication.

- Choosing the right form (pads, gels, or greases) matters to avoid overheating or damage.

- Some silicones may release oils or gases harmful to sensitive sensors or optics.

Silicone TIMs offer reliable heat management for electronics, but selecting the right type is key for optimal results.

Choosing the Right Silicone TIM

Choosing the right silicone TIM depends on your device’s cooling needs and usage. Here’s a quick guide.

- Thermal Conductivity: Choose a TIM with high thermal conductivity (1–10 W/m·K) for better heat transfer.

- Form Factor: TIMs are available in paste, pad, gel, and adhesive forms.

- Paste/Grease: Fits surfaces tightly but can be messy.

- Pads: Easy and clean to apply, with consistent thickness.

- Adhesives: Stick parts together and transfer heat.

Choose the option that best suits your needs and is easy to use.

- Operating Temperature Range: Choose a TIM that remains stable and effective within your device’s expected temperature range.

- Electrical Insulation: Some devices need TIMs that don’t conduct electricity to avoid short circuits. Silicone TIMs can be either insulating or conductive, so pick the right type.

- Durability and Stability: Look for TIMs that last long without drying out, cracking, or losing their heat-transfer ability.

- Compatibility: Check that the TIM won’t react badly with your device’s materials or cause corrosion.

- Application Environment: Select a TIM built to handle moisture, vibration, and temperature changes for dependable performance.

Choose a silicone TIM with the right heat transfer, form, and temperature range, considering electrical safety and durability, to keep your device cool and reliable.

Conclusion: Silicone Thermal Interface Materials (TIMs)

Silicone TIMs are essential components in modern electronics, enabling effective heat management as devices become more powerful and compact. By filling microscopic air gaps between heat-generating parts and heat sinks, they significantly improve thermal conductivity and reduce the risk of overheating.

Choosing the right silicone TIM depends on its thermal conductivity, form, temperature range, electrical insulation, and durability. Proper selection ensures optimal heat transfer, device longevity, and stable performance in varied environments. Silicone thermal interface materials offer a cost-effective, versatile, and durable way to ensure efficient heat management, essential for reliable electronic device performance.